- CFO Tech

- 3 min read

How India Inc is boosting productivity by using intelligent technologies

Assembly lines are becoming less dependent on humans-the shop floor foreman's holler is headed toward extinction. Instead, data and intelligent technologies have taken charge of factory machines, instructing them on tasks that need to be completed.

Assembly lines are becoming less dependent on humans-the shop floor foreman's holler is headed toward extinction. Instead, data and intelligent technologies have taken charge of factory machines, instructing them on tasks that need to be completed.

The smart shop floor concept is being increasingly adopted, with almost all leading manufacturers in the country digitising factories to optimise operations and boost productivity.

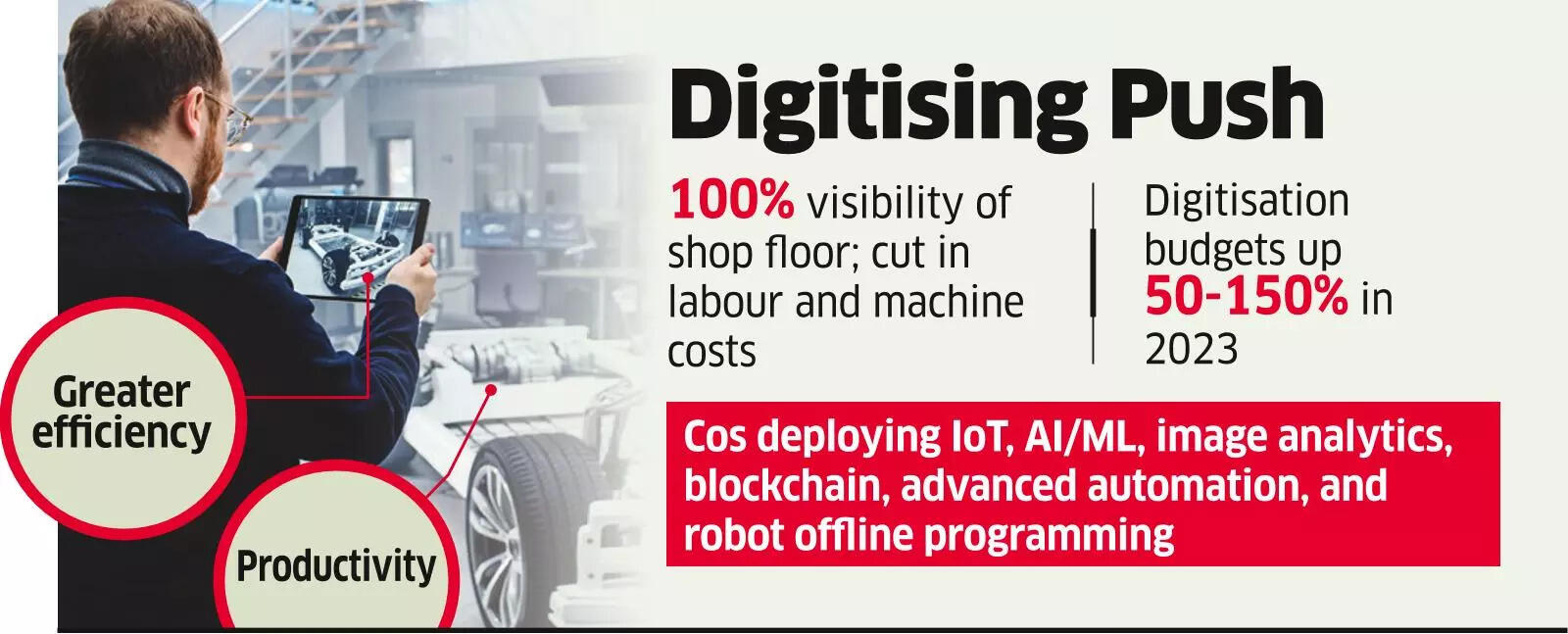

This push toward Industry 4.0 is prompting Indian conglomerates and large companies-such as Larsen & Toubro (L&T), the RPG Group, MG India, Hyundai and Hindustan Zinc-to ramp up investments to digitise factory floors, top executives told ET.

Diversified conglomerate RPG Group increased its digital investment 50-150% in 2023 over the previous year across companies. It's also doubled the overall digital teams at an aggregate level.

"Commensurate with that, our benefits also increased multifold," said Rajat Bhargava, CEO, speciality business, and head, group transformation, RPG group. "Ceat Tyres is the first tyre company in the world to get Lighthouse certification by the World Economic Forum on the back of a comprehensive digital transformation."

Multiple use cases resulted in process scrap reduction, machine uptime increase, lower maintenance cost and energy cost reduction, Bhargava said.

The immediate benefit of digitisation is that it gives 100% visibility of the shopfloor besides reducing labour and machine costs.

All the shop floor automation at engineering company L&T is data driven. It has reduced the cycle time in autonomous welding by 20% and manpower cost by 50%, saving Rs 55 lakh per month and more than Rs 5 crore per year. The company reinvests this money in making factories smarter.

"We are planning to implement 5G in some of our factories. With that the latency speed of machines/robots reduces. We are also training our manpower in AR/VR," said Mahesh A Chikodi, group chief digital officer, L&T. "Intelligent automation, including AI and generative AI, are proving crucial to solving the massive productivity crisis unfolding in front of us. At L&T we are moving up the value chain from automating only rule-based, large-volume transactions to providing real-time business insights supporting strategic goals."

At MG Motor India, shopfloor digitisation includes online displays with graphics to visualise equipment health, said director, manufacturing, Ravi Mittal. The focus this year is on predictive equipment maintenance and the implementation of real-time monitoring, control mechanisms for tracking consumption and flow monitoring and virtual reality-assisted training for new employees.

"This approach provides a simulated assembly line configuration, offering a comprehensive understanding of tasks and production flow," said Mittal. The company is progressing on end-to-end digitisation with an increase of more than 50% in initiatives dedicated to enhancing shopfloor efficiency.

In 2023, Vedanta Group unit Hindustan Zinc undertook key technological initiatives in the areas of equipment tracking, collision avoidance, tele-remote operation of equipment and online monitoring of processes and services for better control through a central control room, said Arun Misra, CEO.

COMMENTS

All Comments

By commenting, you agree to the Prohibited Content Policy

PostBy commenting, you agree to the Prohibited Content Policy

PostFind this Comment Offensive?

Choose your reason below and click on the submit button. This will alert our moderators to take actions